refill service of Z-Printer cartridges + supplies Phone: +49 341 / 99 39 60 39 Mon - Sun 10.00 - 22.00

Your basket is empty.

Categories SLS-DIP-Coating

SLS-DIP-Coating

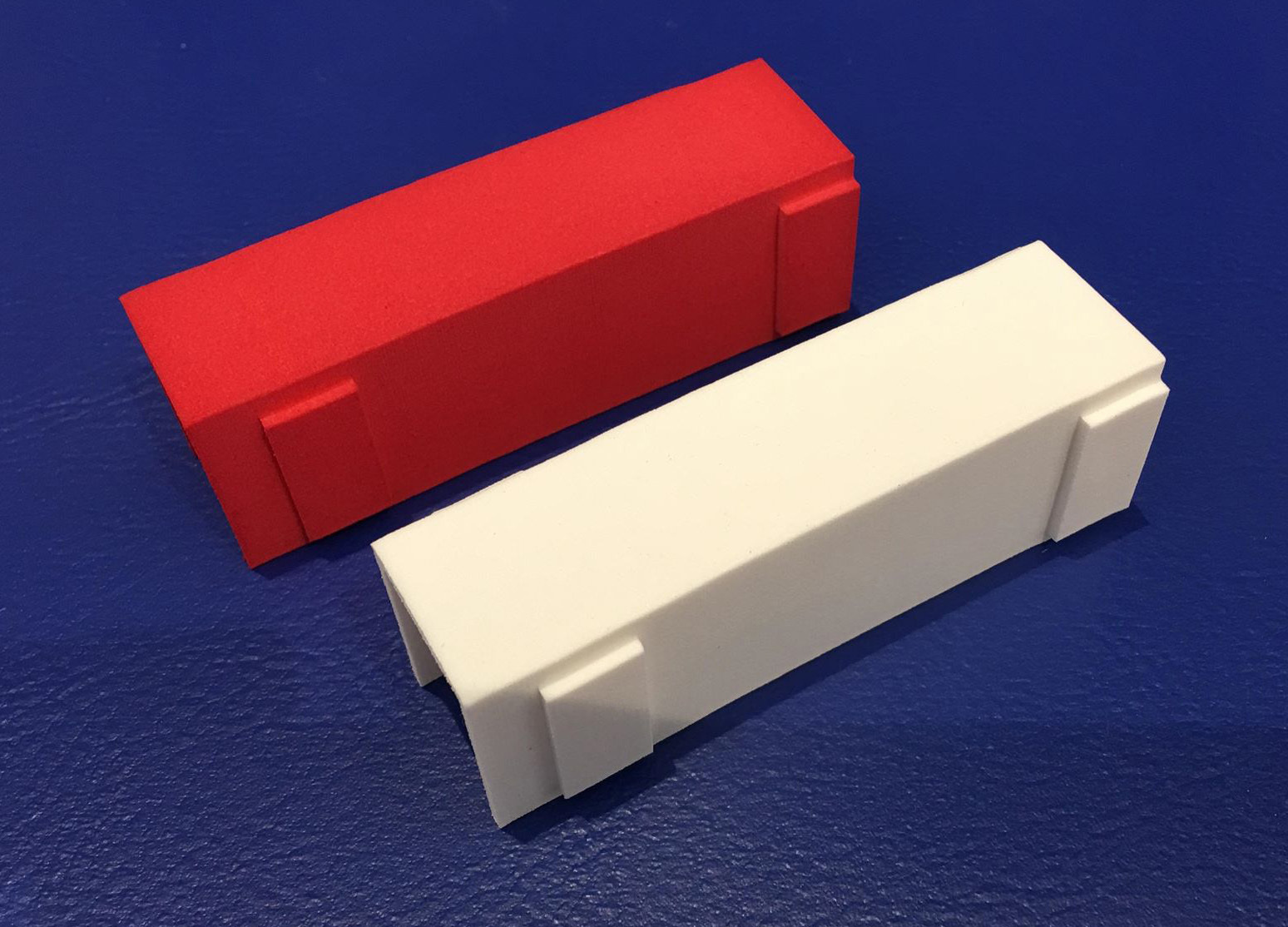

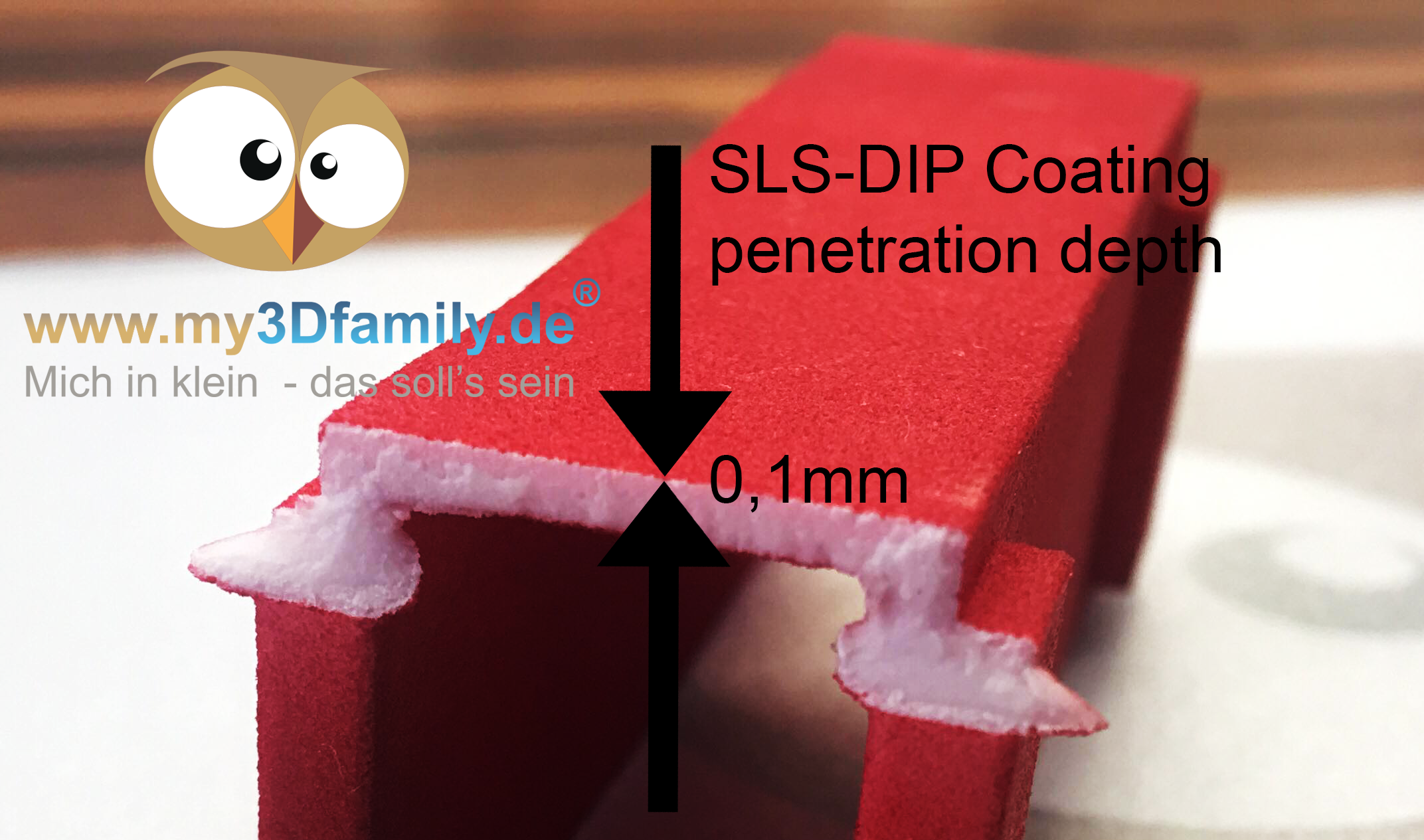

Our SLS DIP Coating products are specifically designed to color SLS printed parts. The colors are specially enriched with nano-quartz pigments to offer you an excellent quality.

Due to very high demands, our products will be available again from 28.06.2019.

|

Advantages of our SLS DIP Coating:

|

|

|

Consumption calculated on an example:

|

|

|

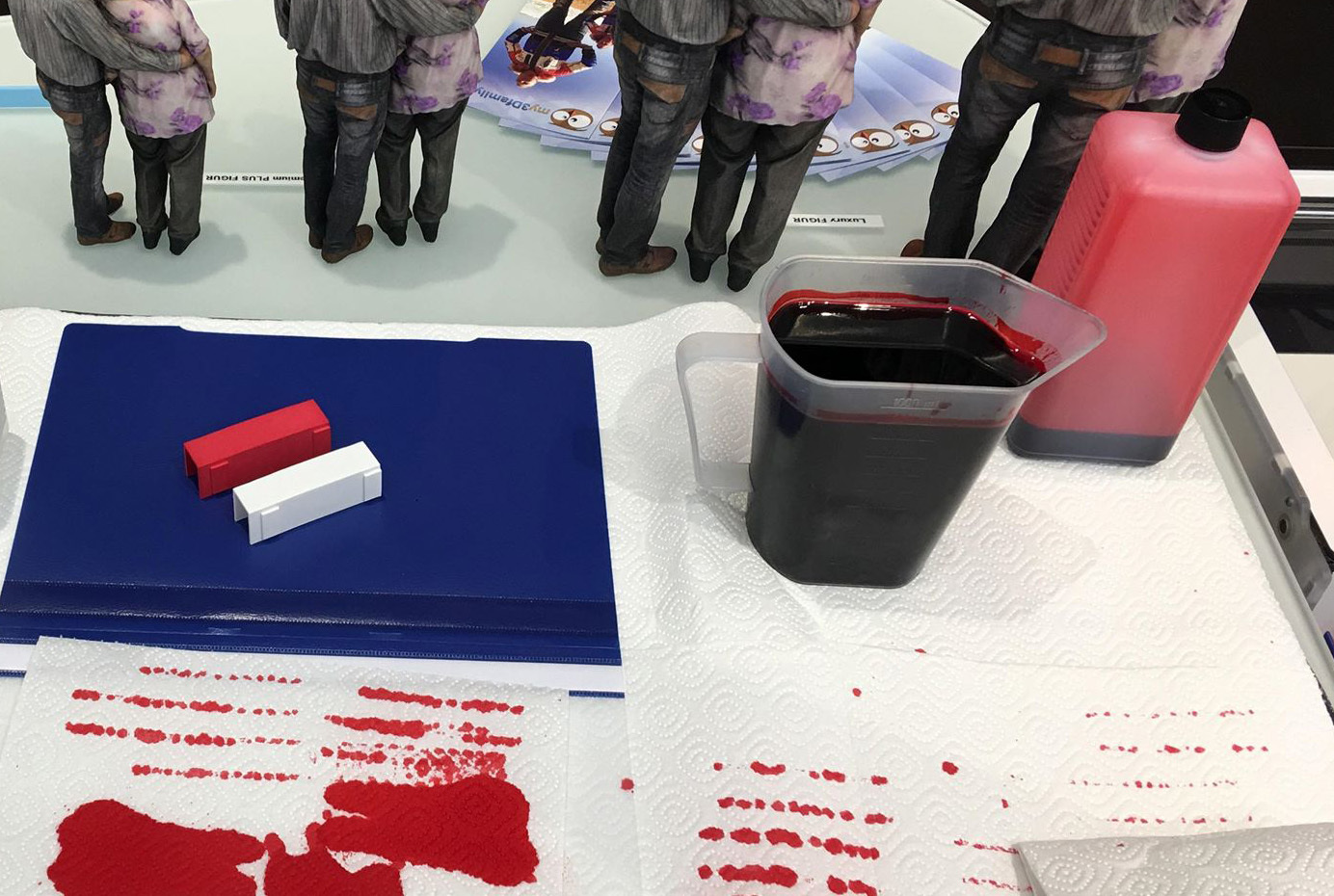

Application of our SLS DIP Coating:

|

|

Display per page

Sort by

New SLS DIP Coationg cyan 500ml229.00 € *Delivery period: 7-10 working days

Delivery weight: 1 kg

|

New SLS DIP Coationg black 500ml249.00 € *Delivery period: 7-10 working days

Delivery weight: 1 kg

|

||

New SLS DIP Coationg white 500ml229.00 € *Delivery period: 7-10 working days

Delivery weight: 1 kg

|

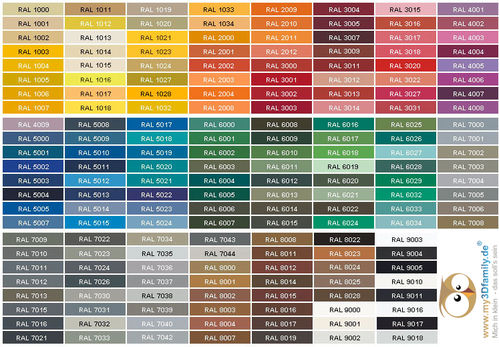

New SLS DIP Coating "special color" 500ml329.00 € *Delivery period: 14 working days

Delivery weight: 2.5 kg

|

||

New SLS DIP Coationg testpackage 4 x 500ml899.00 € *

Old price

917.00 €

Delivery period: 7-10 working days

Delivery weight: 2.5 kg

|

New SLS DIP Coationg black 2,5l1,190.00 € *

Old price

1,245.00 €

Delivery period: 7-10 working days

Delivery weight: 3 kg

|

* Prices plus VAT, plus delivery